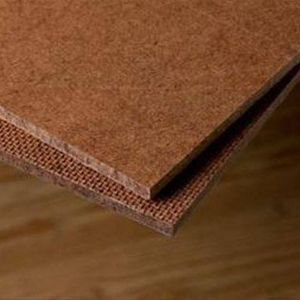

Hard Boards

Hardboard is produced in either a wet or dry process. The wet process, known as

the

Mason Method,

leaves one smooth side and one textured side as a wire mesh is used to allow

moisture to escape.

Dry processed hardboard is smooth on both sides.

-

Standard Hardboard

>> Read More >>

Application:

- Automotive interior trims

- Shoe heel manufacture

- Fibre drum lid manufacture

- Clock backing

- Photo frame backing

- Furniture elements

- Partitions etc.

Salient Features :

- Manufactured under the ISO 9001 certified system.

- Manufactured using plantation species of timber.

- Engineered to meet all requirements under IS:1658.

- Good mechanical properties due to high density.

- No Formaldehyde emission.

- Available in the thickness range of 2.5mm to 6mm.

>> Read Less >>

-

Oil Tempered Hardboard

>> Read More >>

Application:

- Automobile interior trims

- Shoe heel manufacture

- Applications requiring improved resistance to weathering.

Salient Features :

- Significantly improved mechanical properties.

- 100% reduction in water absorption characteristics.

- Used in value added applications by automotive trim

manufacturers.

- Available in the thickness range of 3mm to 6mm.

>> Read Less >>